NPW (Nissan Pump Mfg. Co., Ltd.) is an only aftermarket supplier who manufactures water pumps in Japan. NPW specializes water pump manufacturing for Japanese name cars and trucks such as ACURA, DAIHATSU, FUSO, HINO, HONDA, INFINITI, ISUZU, LEXUS, MAZDA, MITSUBISHI, NISSAN, SCION, SUBARU, SUZUKI, TOYOTA and UD. NPW has a long standing reputation as being one of the best quality aftermarket water pump suppliers worldwide.

The world we live in today is overrun with material goods. Now the automobile has become an essential part of people's lives. Yet to produce even a single engine component can require immeasurable, craftsmanlike skill.

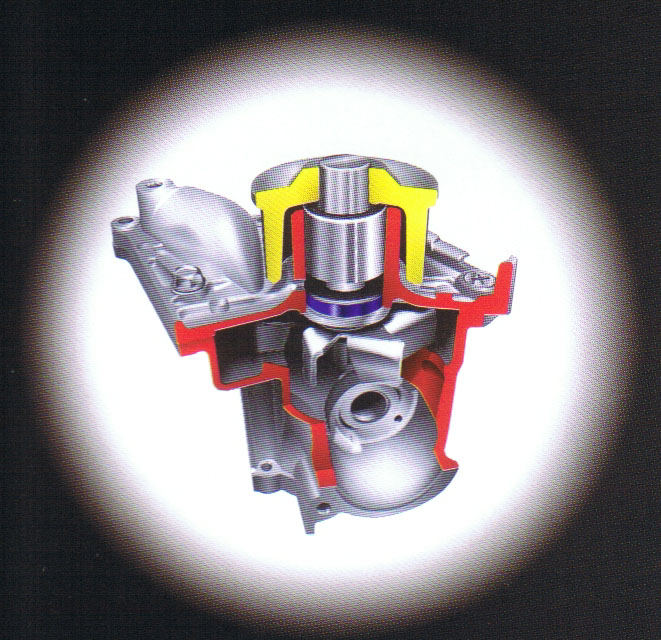

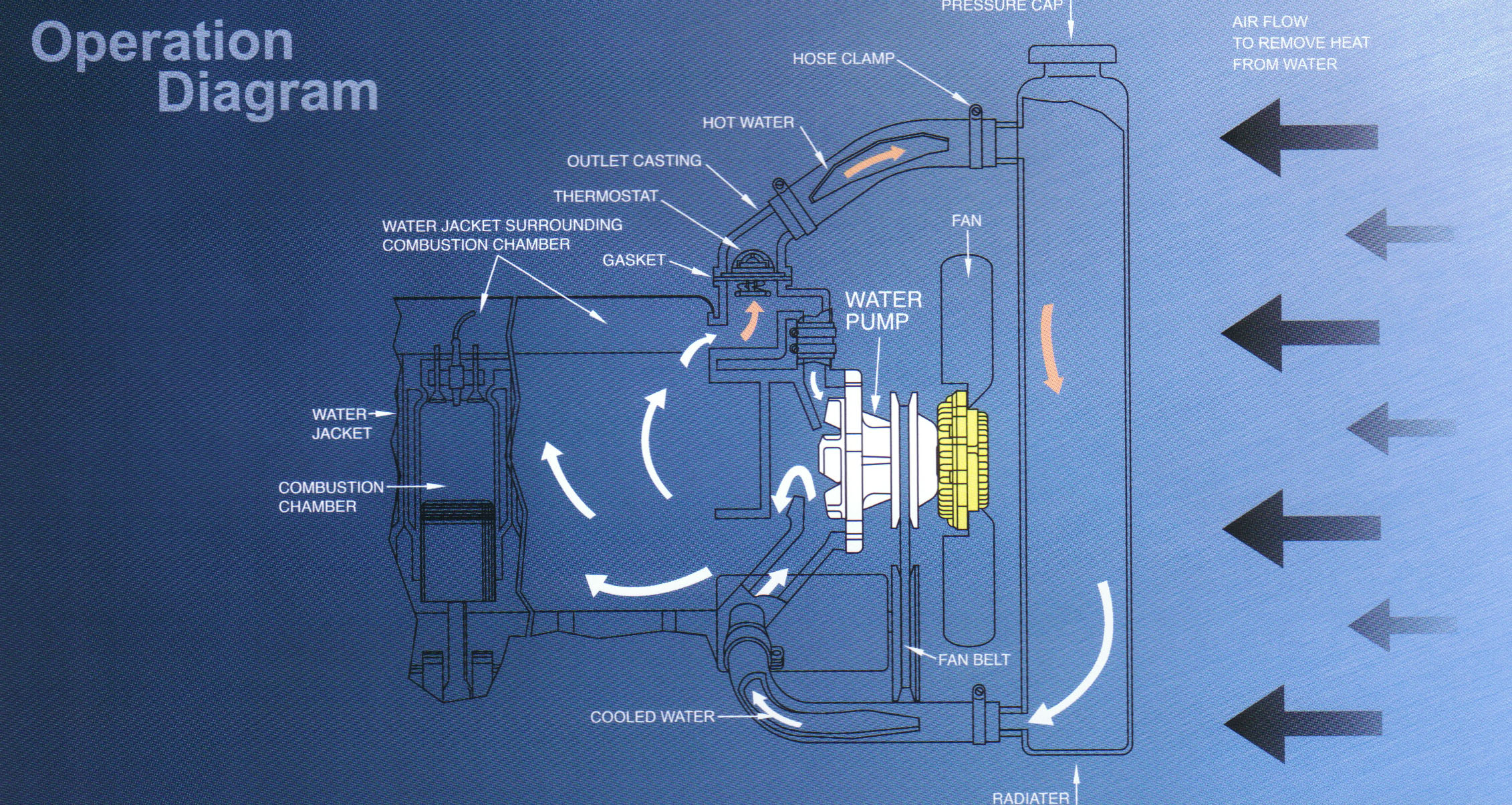

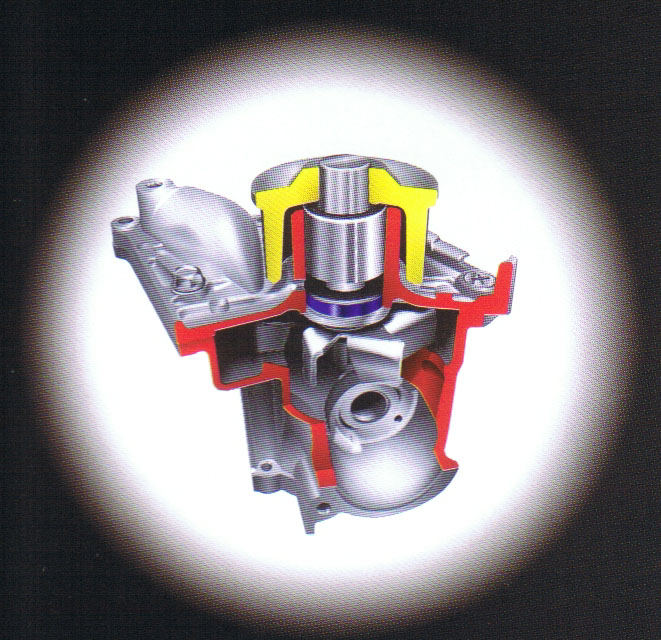

The water pump is just such a component, responsible for cooling a car's engine. A water pump serves the vital role of circulating coolant. Without it, a car could not run for even a mile. The water pump functions under the harshest conditions of any part of the engine. It is exposed to below-freezing temperatures in the winter when the engine is stopped, to nearly 100 degrees [Celsius] when the engine is running. Its materials expand and contract with changes in tempermature.

Yet the water pump must never leak nor stop rotating.

To ensure such performance, precision, micron-level technologies are required.

We live in the computer age. But no matter how much we rely on computers, at a certain point the physical world demands mechanical solutions. At NPW, the design of computer-controlled pumps relies on human touch and intuition. With the craftsman's precision this product has been honed to the level of art.

We live in the computer age. But no matter how much we rely on computers, at a certain point the physical world demands mechanical solutions. At NPW, the design of computer-controlled pumps relies on human touch and intuition. With the craftsman's precision this product has been honed to the level of art.

Since the company's founding, we have gone through the process of trial and error countless times to develop techniques that work. The secret to making world-class products in terms of both precision and durability is maintaining the spirit of the artisan.

To produce goods, of course quality is all-important, but everything starts from the heart. You should put your heart into making each and every item. When you put your spirit into something you make, I believe the customer can feel it. That is what I consider the basic starting point for producing anything--heart.

Doing business? It also begins from the heart. When the customer buys your product, they are showing faith in you, so you return that sincerity with a confidence in what you produce, and a relationship of trust is established. Then a partnership begins to develop--one of the hardest things to accomplish in business and one of the most important. You understand and trust one another, and develop a mutually supportive relationship. Once you establish such a bond of trust, I believe that business will continue to flourish forever.

I believe that products are your real salespeople. And we've gotten this far with that conviction. Also, the brand strength that comes from a partnership is built up by the customer, your partner--fostered by them. That's how I see it.

When I visit a customer I always pay them great respect. I could always choose to send them information about a new product, but a face-to-face meeting is the only way to communicate directly and is extremely vital in that respect.

The Japanese economy has become worn out. While we are a very small company, we will keep our spirits high and remain hopeful as we work hard at producing goodsthe heart of any economy."

From heart to heart, that spirit becomes a relationship of mutual trust and imbues the product with spirit. Mencius said, "Benevolence is man's mind, and righteousness is man's path." NPW will continue to uphold this exalted spirit.

COOLING SYSTEM AND BELTS MAINTENANCE

COOLING SYSTEM AND BELTS MAINTENANCE

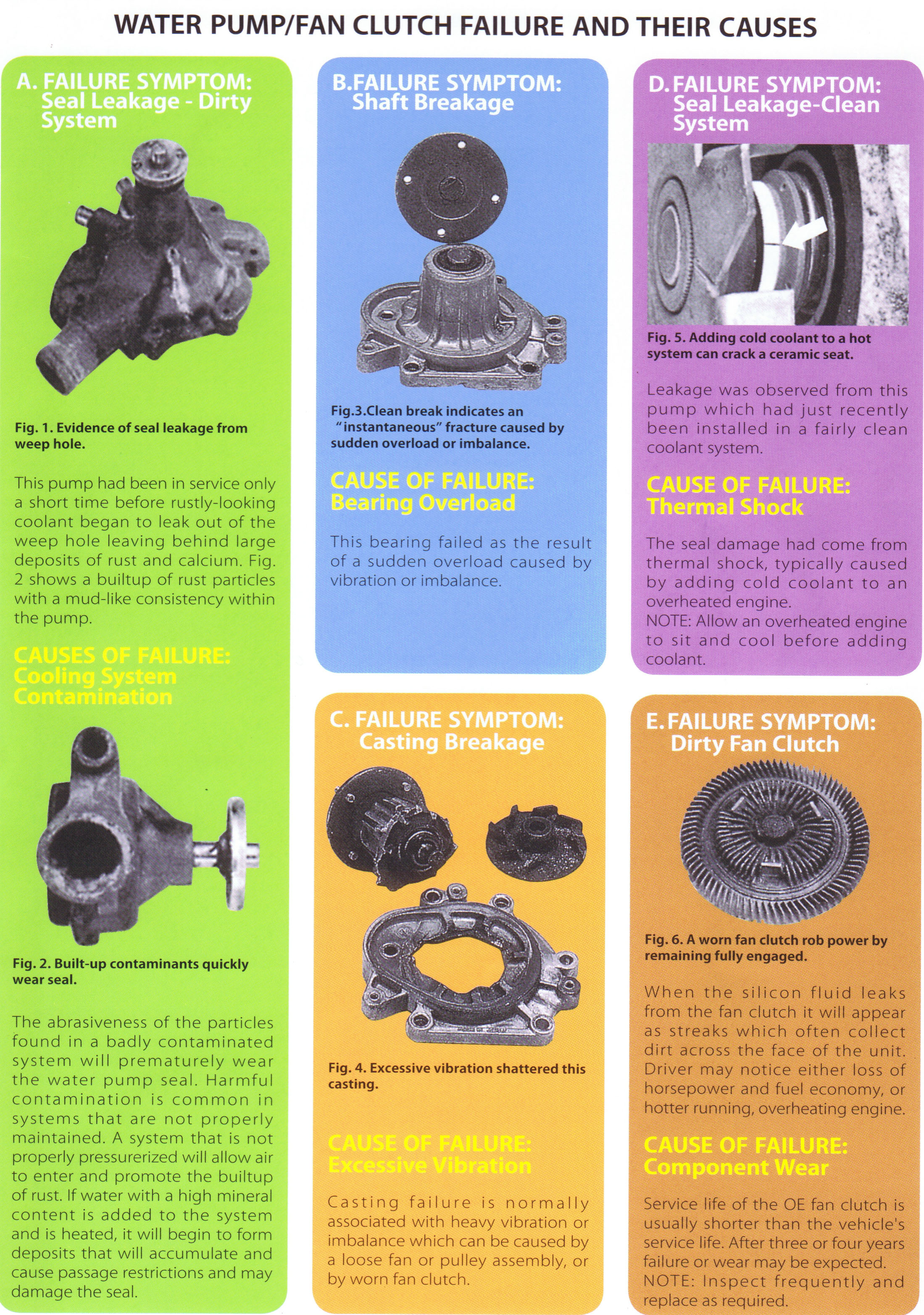

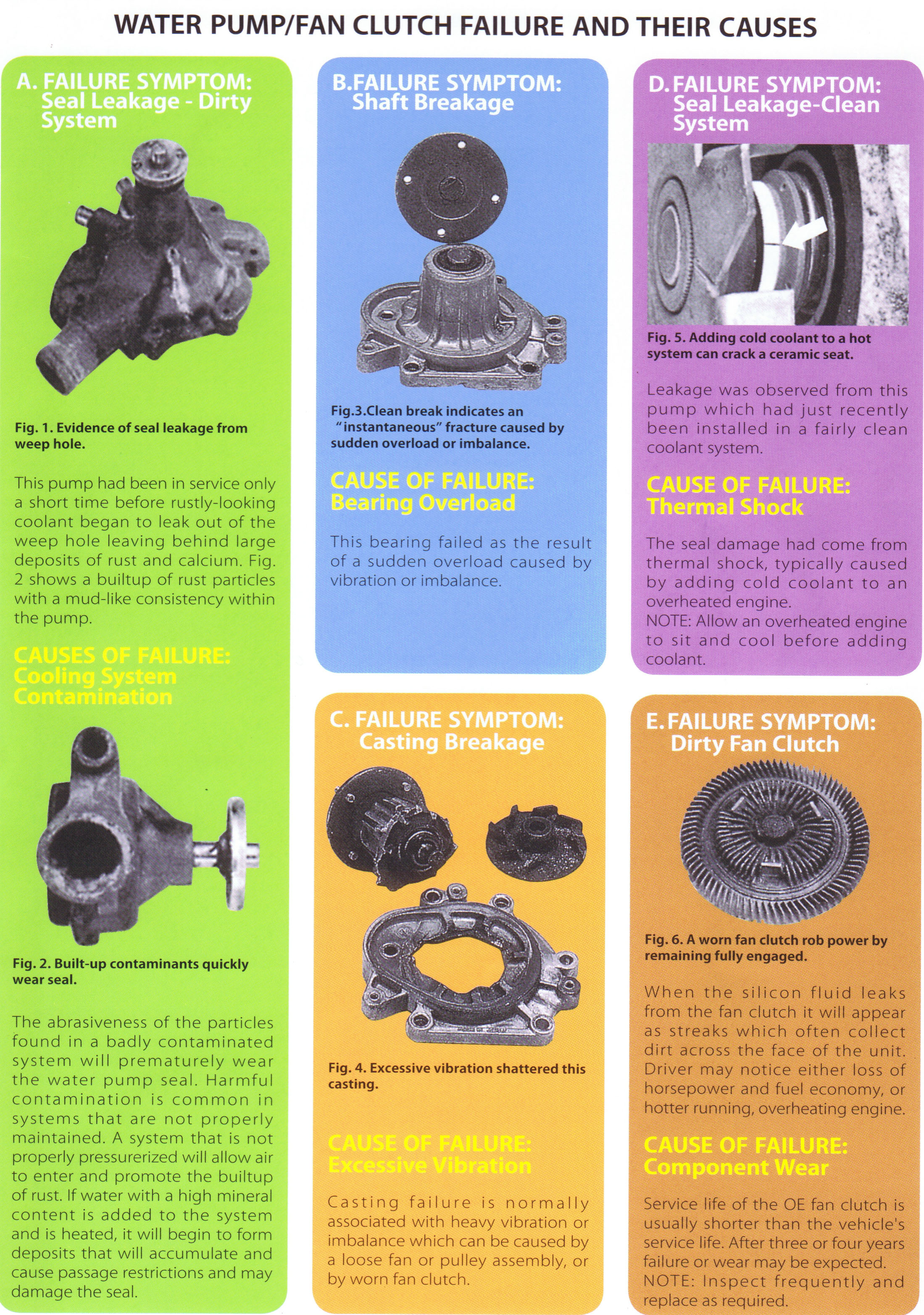

A.COOLING SYSTEM

1. Be sure that the engine is cool before removing radiator cap for

service. NEVER add cold coolant to an extremely hot engine as thermal

shock can damage many internal engine components, including the

water pump seal.

2. Flushing should always be done BEFORE replacing many cooling

system components, especially the water pump, so that contaminants

do not circulate and damage the newcomponents.

B. BELTS

1. Belt tension should be adjusted using a proper tension guage during

regular service intervals. This will limit play and possible belt slippage.

Overtightening must be avoided as it reduces belt life and places excessive

strain on the water pump bearing.

NEW WATER PUMP INSTALLATION

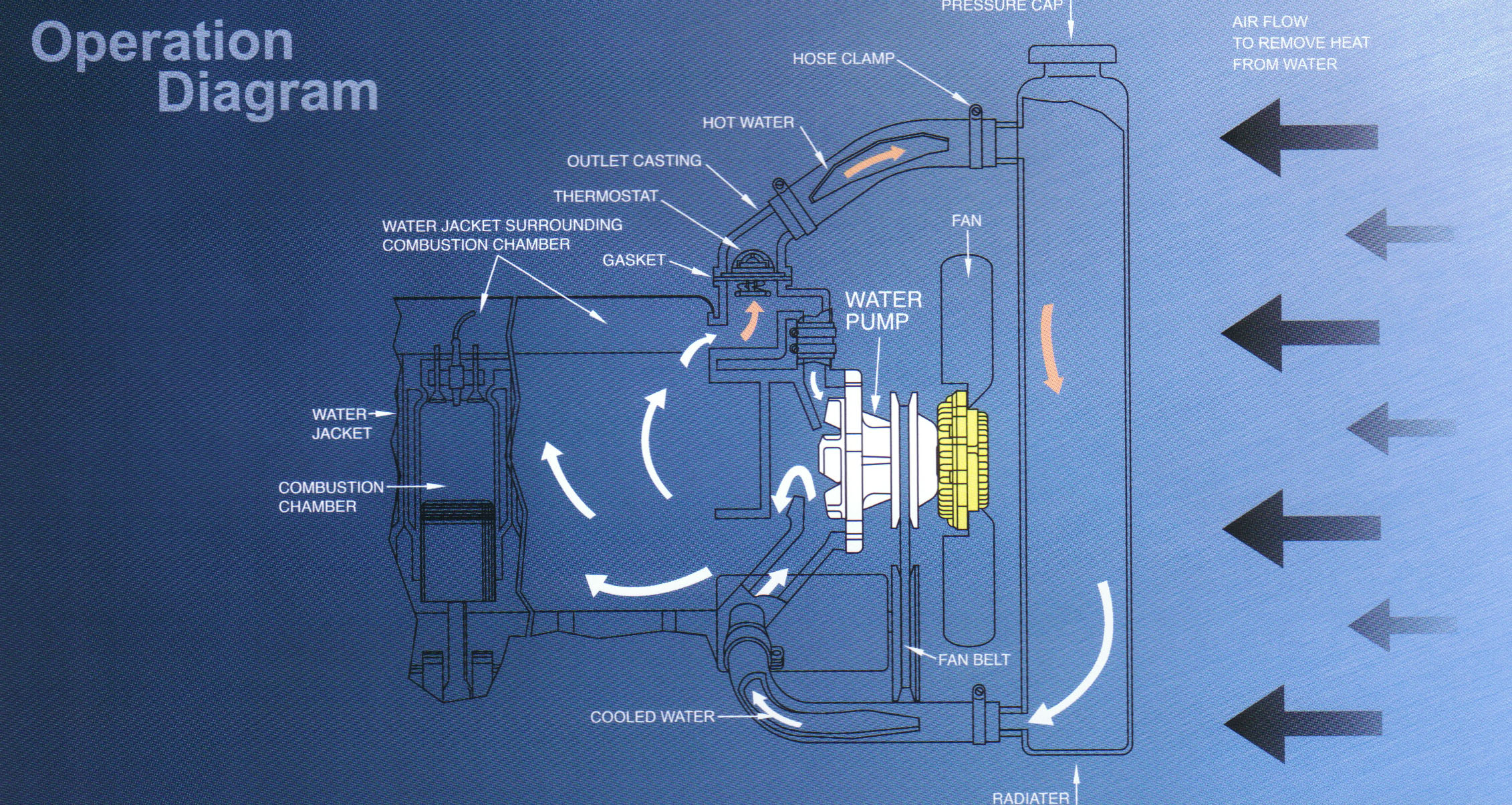

The water pump is the heart of the cooling system. It provides constant

circulation of the coolant through the internal engine passages and through

the radiator. This helps provide even temperature throughout the engine,

eliminating damaging hot spots. New water pump installation should follow

the specific instructions provided with every NPW New Water Pump.

Following is a general list of steps to be observed for proper installation and

water pump life.

A. BEFORE INSTALLING NEW WATER PUMP

1. If the old pump will still circulate coolant through the engine, clean

cooling system with a chemical cleaner and reverse flush all

sediment, rust and scale before removing old pump.

2. Drain coolant from radiator and engine block.

3. Disconnect all hoses from old water pump and fan belts riding on pulley

connected to water pump.

4. Remove fan, fan clutch (if equipped) and pulley from old water pump.

5. Remove old water pump from engine block making note of location

of anyspeciat bolt or fastener.

6. Clean out any built sediment and scale from impeller cavity in engine block.

7. Remove all gasket material from mounting surfaces on engine.

B. INSTALLING NEW WATER PUMP

1. If water pump equipped with a steel back plate covering the impeller,

check all mounting bolts and tighten as required.

2. Coat both side of new gasket with tacky sealer and position on new

water pump or engine block.

NOTE: If using a self-curing, sillicone type gasket sealer from a tube, do

not apply excessive amount. Excess may be squeezed out into water

pump and plug up cooling passages.

3. Install new water pump on engine block-DO NOTFORCEPUMPON BY

STRIKING ENDOFSHAFT.

4. Tighten mounting bolts gradually and evenly in a staggered sequence

to vehicle manufacturer's torque speficications.

5. Turn pump shaft by hand to make sure it rotates freely.

6. Re-install pulley, fan clutch (if equipped), fan, fan belts, and re-

connect all hoses. (Be sure the belts and pulleys are not offset.)

7. Fill radiator with a correct mixture of fresh antifreeze and water and check

for leaks.

8. Tighten fan belts to factory recommended tension. Tension

can be checked with commercially available testers or by measuring fan

belt defection as specified in factory service manual.

9. Install radiator cap and run engine until normal operating temperature

is reached and check for leaks.

NOTE: A small, temporary seepage of coolant from the "weep hole"

located on the lower side of the shaft housing may occur during initial run-

inperiod. This should stop after the seal has been allowerd to "lap in".

10. After operating temperature has been reached, shut off engine

and allow to cool-NEVER REMOVE RADIATOR CAP WHILE ENGINE IS HOT.

11. Remove radiator cap (only after engine has cooled) and top 0f

radiator with additional antifreeze and water mixture.

|

We live in the computer age. But no matter how much we rely on computers, at a certain point the physical world demands mechanical solutions. At NPW, the design of computer-controlled pumps relies on human touch and intuition. With the craftsman's precision this product has been honed to the level of art.

We live in the computer age. But no matter how much we rely on computers, at a certain point the physical world demands mechanical solutions. At NPW, the design of computer-controlled pumps relies on human touch and intuition. With the craftsman's precision this product has been honed to the level of art.  COOLING SYSTEM AND BELTS MAINTENANCE

COOLING SYSTEM AND BELTS MAINTENANCE